Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

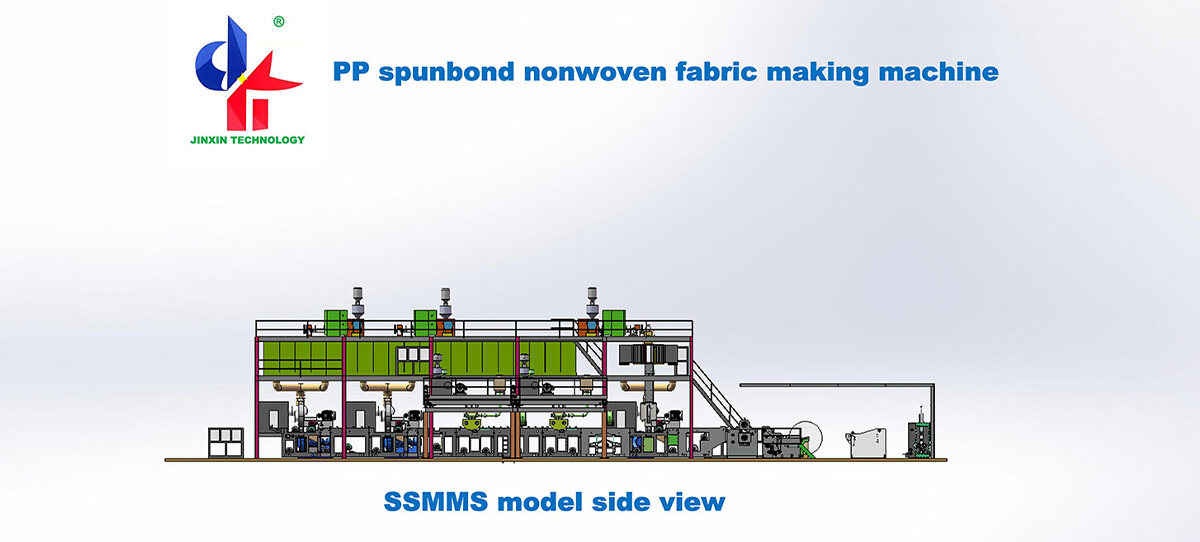

Машина для производства нетканых материалов SSMMS 1600 мм

Important parts of the machine include the drum section and the opening roller, which are made of a simplified body, corner nails, flanges, hollow shafts, etc. The spiral-shaped installation of corner nails on the cylinder. The beater's tangential direction is where the raw materials fed from the cotton input enter.

| Model | JX-SSMMS |

|---|---|

| Product Width | 1600mm |

| Equipment Size | 60*18*12m |

| Mechanical Speed | 600m/min |

| Gram Weight | 8-120g/m2 |

| Daily Output | 10-16T/Day |

| Transformer Capacity | ≈1350KVA |

| Power Consumption | 1200°-1850°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

What are the components of a non-woven fabric machine?

1.The drum part and the opening roller are important components of the machine, which are composed of a simplified body, corner nails, flanges, hollow shafts, etc. The corner nails installed on the cylinder are arranged in a spiral shape. The raw materials fed from the cotton inlet enter along the tangential direction of the beater. Under the action of the rear fan, they rotate around the outer surface of the agitator. Its advantage is that the residence time of raw materials in the machine is prolonged, and the number of hits of raw materials is increased. Therefore, a good loosening effect and high impurity removal efficiency have become one of the remarkable characteristics of this machine. Another notable feature of the non-woven equipment is the opening strength, that is, the rotation speed of the opening roller, which has an online adjustment function. To facilitate the formulation of process parameters, the opening strength is divided into 1-10 levels, which is automatically converted into the speed of the opening beater by PLC program, and the operation of the frequency converter of the opening beater is controlled to realize the online adjustment function of the speed of the beater. Change the speed of the beater and stop to replace the pulley.

2.Compared with non-woven machinery, its advantages are self-evident. The dust removal grid device is the main component of the non-woven equipment and is composed of a dust removal rod, a regulating plate, a connecting rod mechanism, and a stepping motor. The dust-proof rod is divided into two groups, the initial installation angle is 10 ', and the maximum angle is 40'. The machine drives the linkage mechanism by two stepping reduction motors to synchronously adjust two groups of dust rods. The installation angle of the dust-proof rod can be set to seven levels on the control panel according to the raw material conditions and process requirements. The installation angle difference between each grade is 5. Similarly, the installation angle of the dust bar is changed to online adjustment.

3.Decontamination device is an indispensable part of non-woven machinery, mainly composed of a decontamination box and decontamination beater. The garbage collection box is a ladder-type box, and the lower part is equipped with garbage treatment thugs. A thug is a 6-blade blade driven by a gear reduction motor through a roller chain. Its garbage treatment status can be set as continuous garbage treatment or interval garbage treatment through online adjustment (garbage treatment time and garbage treatment interval can be set arbitrarily according to process requirements). One side of the garbage collection box is connected to the garbage discharge (lint absorption) pipe, through which lint impurities can be sucked into the dust filtration system. The bottom surface is equipped with a roller, which can be pulled out of the machine to observe the cotton falling.

4.Pneumatic control system: when the current square fan is not started, the cotton opening drum cannot be started, which can effectively prevent traffic congestion, avoid machine damage, and maintain normal production.